Infrastructure with customer delight as our primary aim, we ensure your plate is served with the most aromatic and quality rice. We have the best in class infrastructural setup comprising of state of the art machineries and advanced processing, quality control, packaging & warehousing units to offer you the finest rice in the world. Spanning in a total area of 20000 sq. mtr. our facility is equipped with all kinds of machines starting from rice stone separator, laboratory rice husker, length grader, rice grader machine to multi grader. Our infrastructure produces the most edible rice i.e. rice that is sufficiently milled and free of husks, stones, and other non-grain materials. Our packing machines allows us to offer customized packaging in any size and packing material as per client's requirement.

Procuring Rice forms an important phase of the export. The procurement requires a thorough and an appropriate understanding of the Rice market. It also requires the exporter to be equipped with the farmers as well as the chain of distributors. We, PRMCS, are associated with a chain of farmers who have been farming Rice since decades and are hence, well acquainted with Rice. For ensuring premium quality of Rice, PRMCS is associated with Kaccha Aarti, Pakka Aarti and a chain of farmers. Kaccha Aarti comprises of the intermediaries between the farmers and the company. We have a team of skilled Kaccha Aartis who are helping us in procurement of Rice. Our experts Pakka Aarti are across Pakistan and they procure Rice from renowned and recognized farmers across the entire region.

Storage : Storage of the paddy is done at a particular moisture level in all the three storage modes.

Silos: Safest Storage Mode

Ware House: Safest Storage Mode

Open Stack : Safest Storage Mode

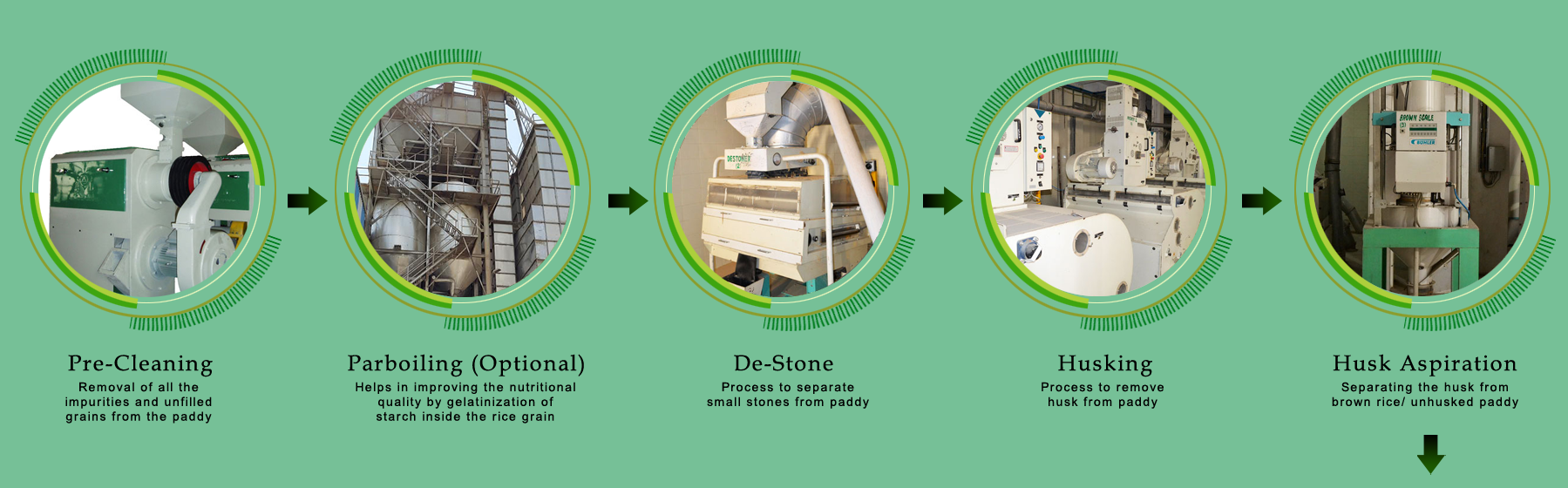

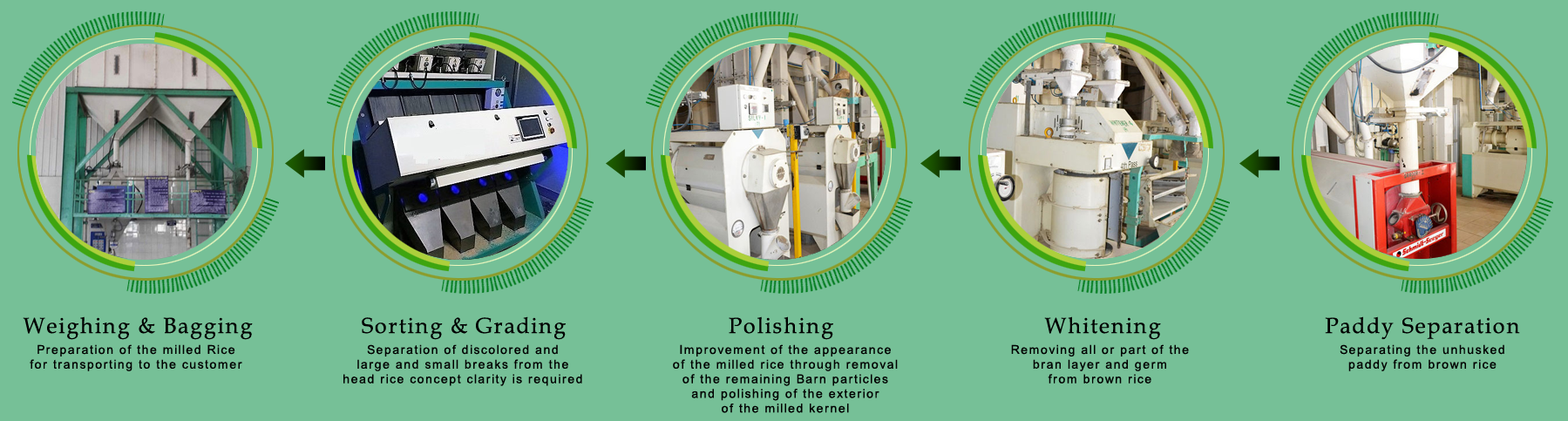

Rice in its natural form is inedible. Therefore, milling and processing of the Rice is required for attaining the desired quality of Rice. In our Rice mills, we process the Rice for making it polished and edible. The main goal of milling is the removal of Barns and Hulls from the Rice so that its consumption becomes possible. Rice is the basic primary product obtained from Paddy after Paddy is processed. This Rice is reprocessed for obtaining varied secondary and tertiary products. Here are some of the operations done to create the final product.

The exposure of paddy to gradual drying processes and controlled temperatures reduce the unneeded moisture prevalent in the paddy. For ensuring the drying of the paddy Rice appropriately, our drying plant comprises of fully mechanized and automatic gradual drying systems having on line sensors for controlling the temperatures. These can dry 100 tons of Paddy per day. We ensure taking appropriate care so that none of the delicate portion of the Rice breaks while processing. Our technological solutions make us take every measure for avoiding Bacterial infection, fermentation or fungal infection so that we keep the hygiene and the natural aroma intact.

Exposure of Rice grains to steam for removal of Hull and Barn layer is known as Parboiling. Though this process appears to be a very simple process yet the taste as well as the aroma gets hampered if the normal water is used for steaming. We, PRMCS, have a committed Parboiling plant furnished with soaking bins that are specially designed and possess sensor based controller for handling the temperature of the water. Clarity required-taste and aroma get hampered because of the usage of the normal water-should it be usage of the water with proper temperature because the next point talks about the temperature of the water.

The last and the final step of the overall procedure is the Milling. In this step the seed grains are made to get exposed to varied sophisticated machines like Magnets, Paddy Separators, De-Huskers, Graders, Precision Sizers, De-Stoners, Pre-Cleaners, etc. Our aim is to provide you with the Rice of exceptional quality, well refined and nutritious having perfect aroma. This further makes us ensure having environmental friendly environment that is completely protected against unexpected and unforeseen elements.

Rice in its basic form is known as "rough rice" and is still covered by a non-edible hull or husk. At the mill, rough rice is processed differently to get the desired form of rice.